Sale! | Stucco -10% | montage materials -5% |Valid until 30.04.2024

Sale! | Stucco -10% | montage materials -5% |Valid until 30.04.2024All WMB stucco materials, until installation, must be stored horizontally on an even surface in a dry room. Storage next to the heaters and in places with strong sunlight is not recommended. Additional load on the profiles may lead to deformation and adhesion of particular elements.

WMB repair compound, and WMB StuccoGrunt primermust be stored at the temperature between +5°C and +30°C. Shelf life of WMB repair compound and WMB StuccoGrunt in the original sealed packaging totals up to 6 months. Other installation materials (glue, paint) must be stored according to manufacturer guidelines.

Both the core of our products (polystyrene foam) and the protective coating (polymer-quartz) are flexible materials; therefore, it is very important to apply materials that can sustain flexibility within a broad range of temperatures.

We recommend using low-pressure façade foams for gluing polystyrene foams, such as:

One can also use highly flexible glues for mesh placement, as applied in thermal retrofit systems, e.g.:

Larger and heavier elements can be mechanically supported (bars, nails, screws, supports, etc.) for the time of glue curing.

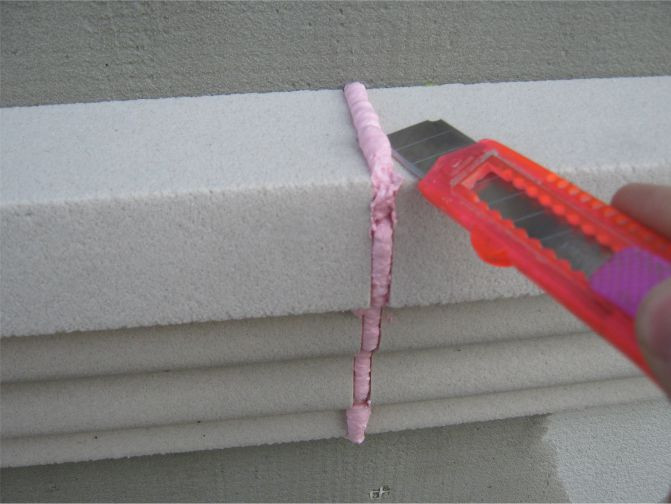

a) While preparing to glue the elements to the surface, place permanently flexible glue (Ceresit CT84) onto the adjacent surfaces of neighbouring elements. It is recommended to keep the appropriate distance (0.5-0.8cm) between the profiles to effectively fill the free gap (see photos 1,2,3). In the case of large cornices (of over 20 cm in height), we recommend applying dilatation every 10-15 m.

|

|

|

| photo 1. | photo 2. | photo 3. |

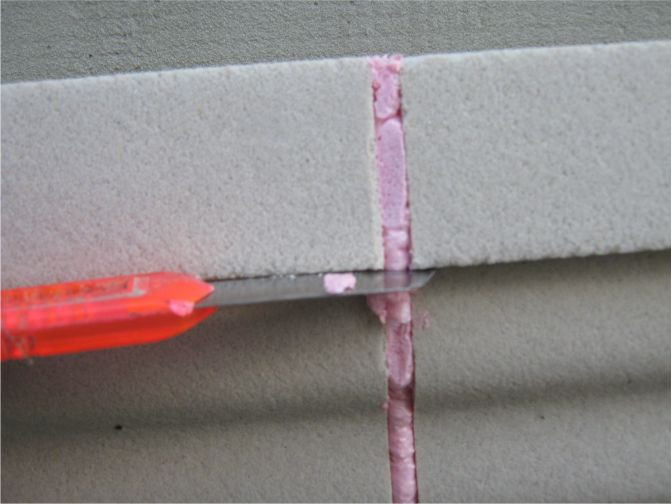

b) After the glue has dried, the joint must be cleaned (see photos 4,5,6), and then primed using WMB StuccoGrunt to remove dust from the joint and to assure better adhesion of the repair compound (putty) (see photos 7,8).

|

|

|

| photo 4. | photo 5. | photo 6. |

|

|

| photo 7. | photo 8. |

After the primer has dried, fill the joint using the WMB repair compound (see photos 9,10,11).

|

|

|

| photo 9. | photo 10. | photo 11. |

On the following day or after about 6-8 hours, water evaporation may cause formation of a delicate cavity. Abrade the profile connection, and replace the WMB repair compound (see photos 12, 13, 14). High air humidity may prolong the time of repair compound drying.

|

|

|

| photo 12. | photo 13. | photo 14. |

c) After permanent immobilisation of the glued elements (after the glue has cured on the surface), fill the joints between the edges of elements adjacent to the wall, particularly the horizontal sections must be durably filled with the flexible sealing glue. This will prevent water infiltration under the profiles and water stains on the wall.

Recommended sealing glue :

After completing the assembly and after the joints have dried, the elements must be painted with the appropriate paint for facades compatible with the flexible surface of our products. Make sure that the painted stucco products are clean, dry, and dedusted. In the event of poor weather, it is recommended to wait for at least 12 hours, until the stucco elements are fully dry before any paint is applied.

Caution: We do not recommend application of any primers. WMB StuccoGrunt is a primer that increases adhesion of WMB repair compound. It must only be applied at the site of the joints between the profiles before the application of WMB repair compound.

Why is it that not all paints are suitable for our products?

In the construction industry, there are at least two fundamental types of surfaces:

Remember about adapting the paint to the surface! Application of unsuitable paints may result in cracks on the stucco surface (photos 15, 16).

Recommended paints:

Among major technical parameters of paints, one has to point to diffused light reflectance value - HBW. For white colour HBW=100, for black HBW=0. The darker the colour, the lower HBW value. Elements painted in dark colours much more intensively absorb sunlight. This leads to excessive heating of the surface and high tensions, resulting in cracks in the paint layer, while sometimes also in the base surface. We strongly discourage the use of dark paints for which HBW factor is lower than 30.

|

|

| photo 15. | photo 16. |

|

|

| photo 17. | photo 18. |

We expressly discourage the use of silicate paints

These are paints that chemically react with the base surface and may irreversibly damage the polymer-quartz coating of our products (photos 15, 16, 17).

Solvent-based paints are prohibited.

Painting wet stucco elements (e.g. early in the morning or shortly after the rain) may cause bubble formation on the product surface through closing the moisture under the paint coating (photo 18).

WMB shall not be liable for any negative effects (fractures, cracks, bubbles, etc.) resulting from the application of other paints, fillers, and glues than the one from the aforementioned manufacturer.

When performing assembly works, follow technical guidelines of the manufacturers of materials used. Such information can be found on the material packaging, and in their MSDS sheets.

If in doubt, consult the provider of the materials.

The above data, recommendations, and guidelines rely on our best knowledge, studies and experiments, and have been provided in good faith, according to the principles applicable at our Company. The proposed methods of procedure are considered generally applicable, but ever user of the material must make sure in all possible ways, including checks of the final product in appropriate conditions, about the fitness of materials supplied for the intended purposes. Our Company cannot be liable for any losses incurred as a result of incorrect or wrong use of its materials.

Prior instructions expire upon the enforcement of this update.